![]() Contractors are notorious for shortchanging themselves. They often don’t charge enough per hour. Or, put enough hours in the Job.

Contractors are notorious for shortchanging themselves. They often don’t charge enough per hour. Or, put enough hours in the Job.

How about you?

Do you know if your prices are right? Do you know if you are properly bidding your Jobs?

The bottom line is the bottom line. Hurray for you…if you are making all the money you want, if you are providing a real retirement investment program for yourself and your team members and if you could take a major hit to your business (disaster, disability, divorce?) and still be in positive cash flow. If so, you can stop right here.

If not, you can fix your business and get really profitable. Money buys options…for you, your family, your team and your community. I love a selling price increase because it is the only thing that you can do – mathematically – that will increase the top line and the bottom line without creating any additional expense. I always support a selling price increase. You deserve it for the wonderful, valuable, risky work you do. However, it is a good idea to also determine if you are putting enough hours into your Job bids and Flat Rate tasks.

Have You Got the Time?

You can find out if you are building enough time into your service tasks and bid jobs by Job Costing.

That said, don’t bother Job Costing service work. Don’t fuss about individual task performance. Look at the Service Department as a whole. Review the Service Department sales and direct costs (Cost of Goods Sold) weekly…month to date and year to date. Compare the actual amounts to budget. Then, occasionally “audit” a Flat Rate task and measure the actual data for a month or two. You can add time to your tasks, and see the overall impact on the Department numbers.

Do Job Cost “big” work…renovation, installation, remodeling and new construction Jobs.

The definition of a Job:

- More than one day.

- More than one set of hands.

- One person sells it, another team installs it.

If two or more apply, call the sale a “Job” and trigger the Job Folder and Job Costing procedures. Job Cost every Job.

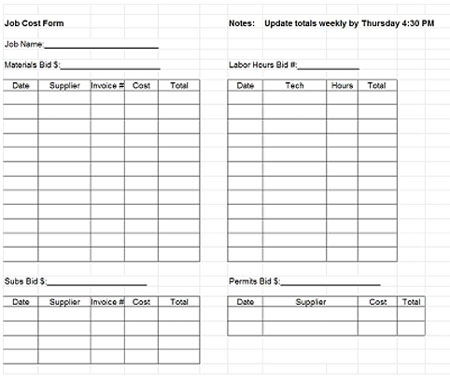

The essentials of Job Costing:

- Comparing bid to actual labor hours. (Don’t convert to dollars. Too much “voodoo” goes into that calculation. Match hours bid to the actual hours it took to do the Job. )

- Comparing bid material cost in dollars to actual material cost in dollars.

- You could also track permits and subcontractors, if you use them.

The game is won or lost by this point. If you create a Selling Price for labor the way I recommend, your hourly Labor Rate should cover overhead costs, too. Job Costing allows us to see if we have at least put in enough time and materials. As a technician, you will notice that this is troubleshooting 101. Nail down a couple of variables. Job Costing helps you figure out what is working and what needs to be fixed.

Keep Track of the Job!

In the office, create a hanging folder for each Job. Name it, using a standard naming convention. You could use something like this:

- Fernwicky_1234_South_110715 (Name_Address_YearMonthDay of signed bid/agreement)

Create two Job Folders for every Job, a blue folder and a red folder. Both of these folders go in a hanging folder in the office. The red folder is the office Job Folder. It’s red because it should flash “warning!” if it is ever outside of the office.

In the red Job Folder, include:

- The original signed bid/agreement.

- The bid Pricing Form. The Pricing Form should have the number of hours bid and a list of the materials and their estimated cost. (NOTE: I’ve got a freebie for Pricing Form for you.)

- Permits and required Job forms.

- Plans and specifications.

- Copies of customer invoices.

- Copies of customer payments.

- The POs or priced invoices for the actual materials used.

- Anything else that will help you deliver this work as promised, stay in compliance and properly account for this Job.

- A Job Costing form where you can tally up actual labor hours (derived by manually pulling from the time sheets or from your Dispatch software program) and the actual materials costs (from the POs/priced invoices.)

Create a blue job folder with copies of the information found in the red job folder. This is the folder that the Lead Installer can take with him or her on the Job. Customize my list to work for you. You don’t have to give the Installer everything the red folder contains. The idea is that the Installer has the information he needs to bring the job in as promised. Yet, he doesn’t have the only copies.

How Did You Do?

Once a week, measure your performance with your team. Meet with the Salespeople and the Installers. Call out the assembled actual performance numbers – hours and dollars – and have the Lead Installer tally up his or her Jobs. You use a Job Costing form like this:

Can You Automate Job Costing?

Sure! Your accounting software may make Job Costing easier and more automatic. Do check and make sure that the data is flowing the way you think it is, or hope it is. There is some advantage to manual Job Costing. It requires that you look at the data. The automated reports are easier to ignore and may be more complicated than you need.

Live and Learn!

Celebrate Jobs that come in at or below bid. Learn from the ones that don’t. You may find that the Salespeople are skimping when it comes to how many hours to include. And the Installers may want the Sales team to pad the bids too heavily to make sure the Jobs come in on time. Work together to develop efficiency without unrealistic expectations.

And, if you are nailing the Jobs for hours and materials, and you are still not making the money you would like to make, you have one more thing to do: Raise your prices.

Business is easy.